CAM also extends its functions to computer assistance in all operations of a manufacturing plant. It is a software used to control machine tools and related things in the manufacturing of workpieces.

After going over this course, you will develop a clear understanding in using CAMWorks for virtual machining simulations, and should be able to apply the knowledge and skills acquired to carry out machining assignments and bring machining consideration into product design in general.CAM software is an abbreviation for Computer-Aided Design and Computer-Aided Manufacturing Software. This course provides you with basic concepts and steps in using the software, as well as discussions on the G-codes generated. It primarily serves the purpose of helping you become familiar with CAMWorks in conducting virtual machining for practical applications. This course is intentionally kept simple. This helps you understand how the G-codes are generated by using the respective post processors, which is an important step and an ultimate way to confirm that the toolpaths and G-codes generated are accurate and useful. One of the unique features of this course is the incorporation of the CL (cutter location) data verification by reviewing the G-codes generated from the toolpaths. Both milling and turning operations are included. The concepts and commands are introduced in a tutorial style presentation using simple but realistic examples. Basic concepts and commands introduced include extracting machinable features (such as 2.5 axis features), selecting machine and tools, defining machining parameters (such as feedrate), generating and simulating toolpaths, and post processing CL data to output G-codes for support of CNC machining. The course covers the basic concepts and frequently used commands and options you’ll need to know to advance from a novice to an intermediate level CAMWorks user. In addition, the machining time estimated in CAMWorks provides an important piece of information for estimating product manufacturing cost without physically manufacturing the product. Capabilities in CAMWorks allow you to select CNC machines and tools, extract or create machinable features, define machining operations, and simulate and visualize machining toolpaths. CAMWorks provides excellent capabilities for machining simulations in a virtual environment. CAMWorks is embedded in SOLIDWORKS as a fully integrated module.

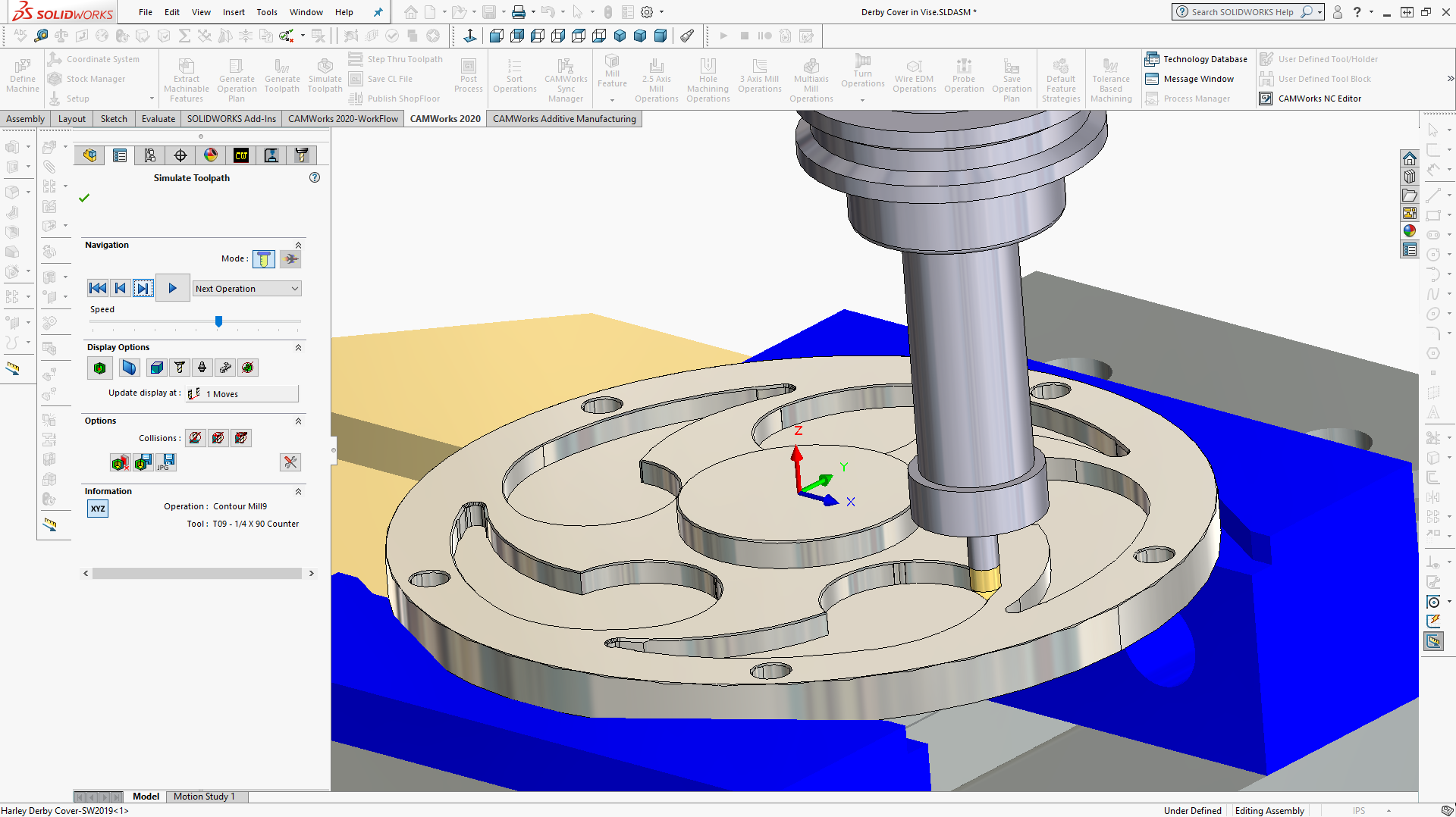

CAMWorks is a virtual machining tool designed to increase your productivity and efficiency by simulating machining operations on a computer before creating a physical product. The CAMWorks Tutorial Training Class and Course will help you learn the core concepts and steps used to conduct virtual machining using CAMWorks. CAMWorks Tutorial Training Class and Course

0 kommentar(er)

0 kommentar(er)